Sun 9 May, HHN day 26: Furler motors all tested positive (… no, not Covid). Removed hot water tank and started to clean the corroded pipework.

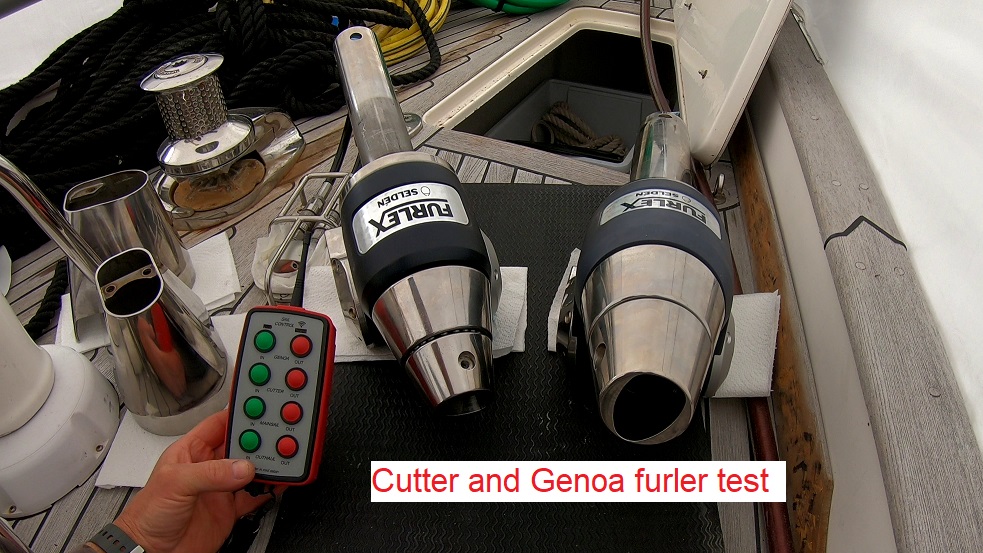

First thing after breakfast, I’m crawling forward on side deck to test the furling motors that I had set up last night. I thought I might have nightmares about them not working or blowing up, but I didn’t. I slept well, thank you. Though I have to say, I’m a tag nervous as I first press the button to activate the mast furler.

But I need not have worried. Within 5 seconds of pressing, the hydraulic oil had filled the new hoses and the motor works perfectly. Same for the cutter and genoa motors. I wouldn’t say they sound any different to before, but at least there is no grouching of metal sound… and they didn’t blow up!

In my mind, I do a little merry jig of joy 😊 Maybe I could have a pastime as a hydraulic furling service technician afterall.

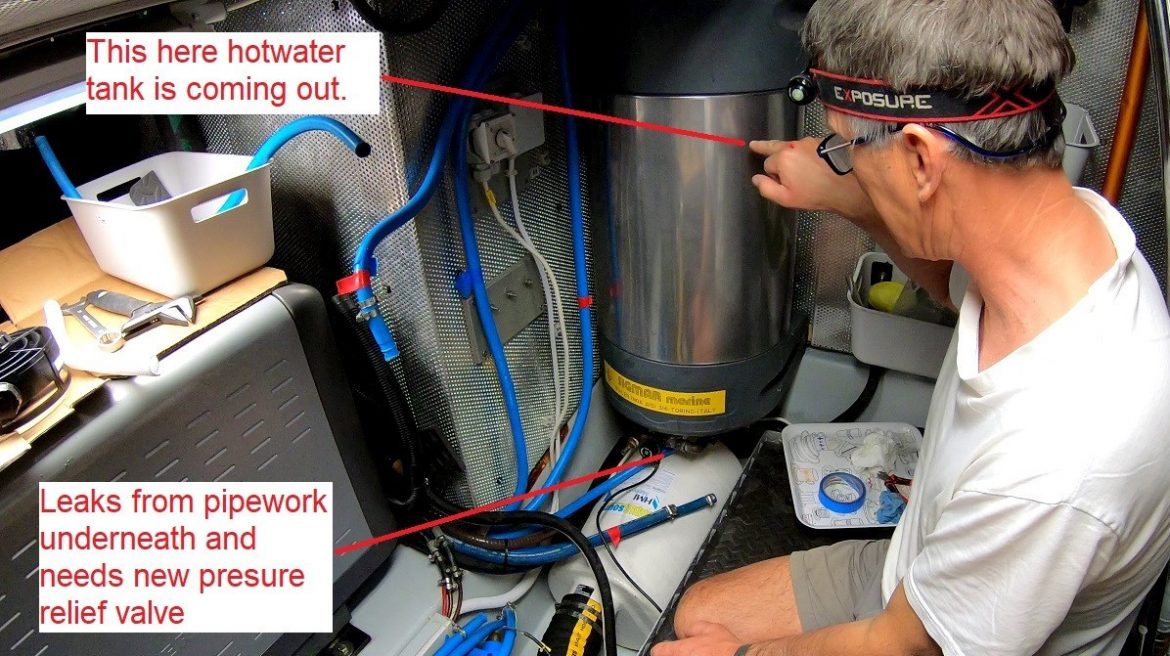

So, what to do next? Which job to pick? It’s pretty chilly outside so no mast work. I leave that to next week when it will warm up again. I should really tackle either dropping the rudder to replace seals, or removing the hot water tank to replace the pressure relief valve. It failed a year ago, plus there are several leaks in the pipework below the tank that need addressing. It’s one of those jobs I have not yet dared to tackle.

I go down into the engine room and inspect how I would remove it. A lot of pipes to remove, the cylinder to drain, and 4 bolts that secure it to the bulkhead. And 2 of those bolts are very inaccessible. I decide that if I actually have the right long-reach socket size, and enough extension bars on my socket set to reach the hidden bolts, then I will remove the tank. If not, then the rudder gets preference. I should just toss a coin really, shouldn’t I?

Well, I have the socket and all the tools required to remove the hot water tank, so decision made. First, I fill 5 gallons into water containers from the taps, because I won’t have running water while I’m doing the tanks. Then I go have a shower to use some of the hot water. And after my shower I run the rest of the hot water down the sink. Surprisingly, it take 20 minutes for it to finally run cold. I do this because I don’t want a sauna in the engine room as I drain the hot water tank.

Removing all the pipes takes a while, plus several other things to remove so I can get to the hidden bolts. Once drained (into the bilge) the tank should be light enough for me to handle, but I’m still not certain what it will weigh or even if I will manage to lift it out by myself.

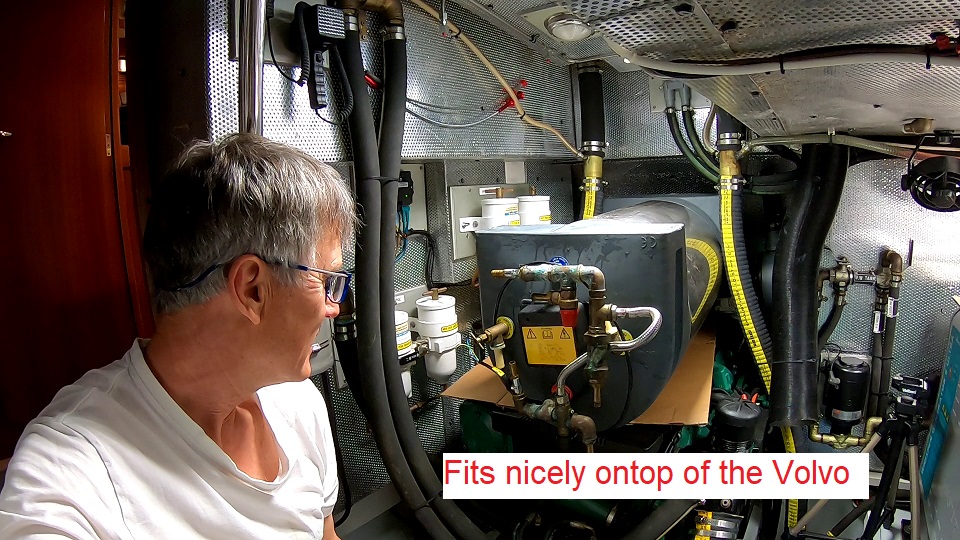

The 4 securing nuts come off easily then it’s the big heave-ho to get it on top of the Volvo. It’s not as heavy as I expected, but still very awkward. As I manhandle it, I have flashes in my mind of news headlines: “Englishman found starving after being pinned to the floor by hot water tank 2 weeks ago”.

Now that it’s secure on top of the main engine, I can at last see all the piping without standing on my head in some weird contortion. They (Hallberg-Rassy) could have tried to make this piping a bit more assessable. Even the thermostat controls are by feel only!

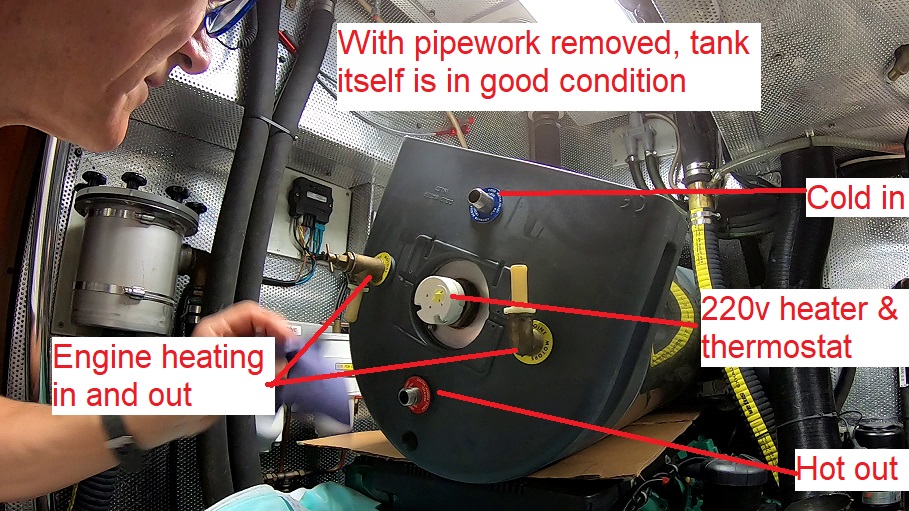

As suspected, the joints on most of the brass piping have failed and are leaking. Lots of calcium and other deposits. But with the piping removed from the tank, what remains looks in very good order.

I take a quick look inside the tank with my endoscope (oh … you don’t have an endoscope? How do you survive without one?) and I’m happy to see it pretty clean. Very little calcium or even sludge in the bottom. One of the plus points about making your own RO water – it is so pure and clean.

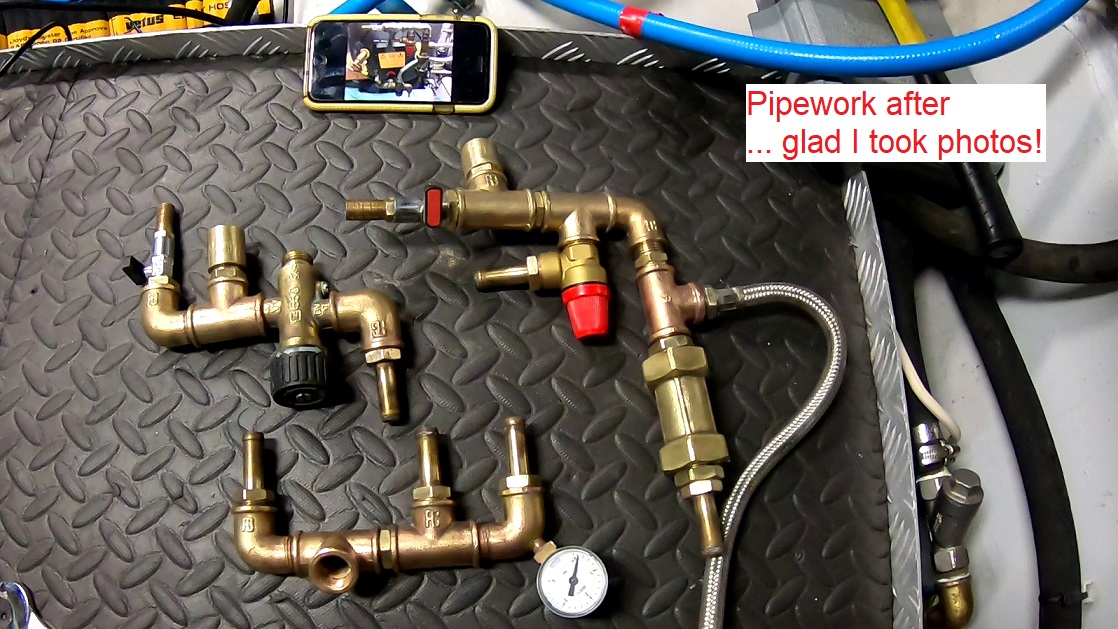

The offending pipework is taken outside and then to Weaver boats where their vice is invaluable for taking it all apart, down to individual pieces. And then back to the boat for a 3 hours session cleaning all the multitude of brass fittings with wire wheels on my electric drill.

It is just about dark by the time I finish my pile of brightly gleaming pipe fittings. I really would not bother with all this work. For the relatively cheap cost, I would normally go out and buy new fittings. But in USA all the thread sizes are unfortunately different to the rest of the world, so the same fittings simply are not available here. I’ll say no more on the subject of uniqueness’s in USA… while I’m a guest here.

Back in the engine room, I deposit all the shiny fittings on the floor pan. They look so nice. And I’m so very glad that I took photos before dismantling. Otherwise it would have been quite a jigsaw puzzle to work out what fitted to what.

It’s been a long day of work, but pretty happy with progress. I really never expected the water tank to go this smoothly. Let’s see tomorrow if getting it back into place is just as simple.

1 comment

I would look in on you Monday.

Comments are closed.