Fri 14 May, HHN day 31: Rudder? Yes, yes, I’m on it, OK? All day in the bilge under the aft berth, replacing swim platform hydraulic oil reservoir and prepare to remove the rudder. Then a lovely dinner on a Fountaine Pajot catamaran, with Ken and Alison.

First, the bad news. I have a water leak ☹. Can you guess where from? Yes, correct, under the hot water tank. It has to be a conspiracy, because in the entire history of 3M 5200 sealant, nothing (let alone pure water) has ever penetrated it! It’s a tiny-tiny leak from just one joint, yielding only about 4ml overnight. Not even enough to see the needle of the pressure gauge to move.

But a dripping coupling is a dripping coupling. I just can’t have it! Ray suggests the 5200 may not have fully cured inside the thread and best leave the water pressure off for a day to see if it seals itself. So that’s what I do. Water pump is switched off for the day and the pressure drained. I’ll try not to think about it until tomorrow.

The good news is that I am now an expert and taking the tank out and putting it back in again, if it comes to that. Maybe 3rd time lucky, as they say.

Ray is here shortly after breakfast and we go and fetch the boom back from the welding shop, using East Coast Marine Rigging’s mast dolly. It has been in for welding since the boom had a multitude of elongated holes at the vang attachment area which are now welded up.

The trip back to the boat is a bit trickier because it’s uphill. But we manage OK and the boom is soon sitting naked (no fittings at all) next to Cloudy Bay. I want to get it completely put back together before I depart back to Europe.

Tempting as it is to start jobs on the boom now, today will be the day I start working on the rudder bearing refurbishment. This means dropping the rudder out the boat, which is no small job considering its size. It also means I will have to dig small, insignificant, tiny hole (in case yard staff are reading this) in the yard to lower it into.

Officially, I should get the travel lift to pick the boat up to give me room to drop it out the boat. But it is not possible to get the travel lift over the boat while the mast is next to it… and I don’t want the mast moved. So secret hole digging over the weekend is the order of play.

But before all that, I need to get inside the bilge where the quadrant is located and remember the sequence to lower the rudder.

Once the aft berth is cleared and I have access to the bilge below, I see the swim platform pump has leaked even more hydraulic oil. The plastic hydraulic oil reservoir has split and I have a new one to replace it. Simple job it would seem, so I decide to get that done first rather than be slipping around in the leaked oil while doing the rudder.

You would think the hydraulic oil reservoir would be easy to remove, but no. The whole pump needs to be removed to get to the screws that hold the reservoir. So easy job? No.

With the new oil reservoir finally in place, I bolt the pump back in position, and that’s when I realise what the root cause of the problem is. The oil reservoir is jammed against a bulkhead with the weight of the pump on it. That’s why the reservoir plastic had failed.

Initially, I try putting spacers behind the mount to pull it away for the bulkhead, but that doesn’t work. Eventually, I end up drilling and bolt a small eye fitting above the pump so that I can “hang” its weight from above, taking the force off the reservoir. Why didn’t they think about simple things like this when installing? Well, I guess hindsight is 50/50 right?

Hence the quick job of replacing the hydraulic oil reservoir takes me through till 2pm. Bummer, half the day gone and I still have not touched the rudder. But changing the reservoir was on my to-do list, so at least I get that job ticked.

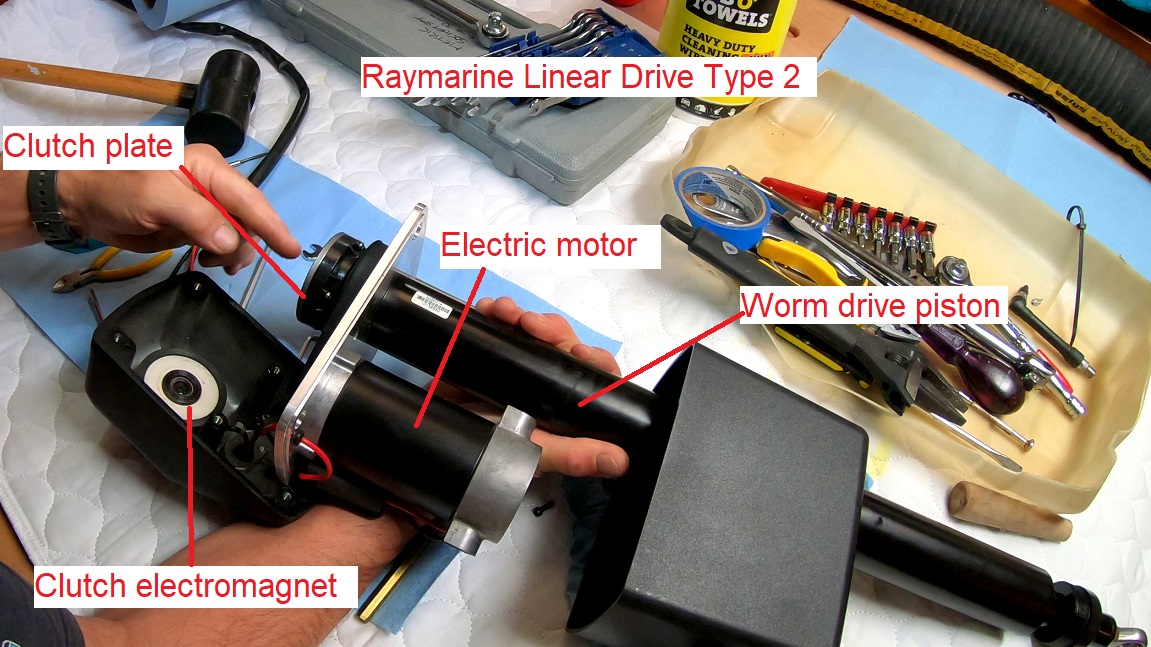

For the rudder, I first remove the Type 2 linear drives for the autohelm. They will go for service at Raymarine. And of course, I can’t resist the temptation and I take one apart to see what is actually in there. My usual curiosity.

I identify all the parts: the motor, the worm drive, and the magnetically activated clutch. I wish I could see Raymarine service it, then I would know what to look out for and how to service it myself. But sadly, the only way to service these in the USA is to send them off to a central service center.

Moving on to the rudder. I have previously (in 2018) had the upper bearing out and sent it for service back at SP3 Steering Systems in France. That was a dodgy operation because we were afloat in Lanzarote, and with the slightest wrong move the rudder would have dropped out the bottom of the boat into the sea, with an obvious sinking feeling!

What I’m actually saying is that the rudder bearing and I have already made friends. But now I have a new challenge. This time, I do actually have to drop the rudder because I need to change the lower SP3 bearing seals. What I’m concerned about is when it gets down to the last 1-2 threads. If the full weight of the rudder is on the connection at that time, it will likely strip the threads. So I have to work out how to avoid that by taking the rudder weight somehow.

I get to that point exactly, then stop for the day. I need to get myself cleaned up now because tonight I have been asked to dine with Ken and Alison on their 44ft Fountaine Pajot catamaran in the marina, at 6pm.

We previously met Ken in Bermuda at the end of 2019, when they had a monohull called Beetle Juice. Now they own this new cat. Actually, they have 3 cats. A nice one that they live on, and 2 fluffy house cats who don’t seem amused at the selling of their comfortable family home to move full time on an alien floating platform!

Considering Fountaine Pajot are built for the charter market, this one is quite special. An “owners” version. One hull is a master berth and en-suite (huge). The other hull is guest cabin, heads and an office. All very spacious and luxurious. And as I get the tour I make a mental note to myself: “Don’t let Oana see this floating palace, or there will be trouble!”

The last time we were on a catamaran as nice as this was in Grenada, on a Knysna 50S, made in South Africa. It really does get me thinking again: is a catamaran the answer to those uncomfortable days on Cloudy Bay? Hmmm, could I really contemplate swapping Cloudy Bay for another boat? For a boat that doesn’t sail to windward, doesn’t heel, doesn’t have a nice sea motion? I wonder.

Anyway, thinking aside, Ken cooks on the BBQ and we have a lovely evening chatting, comfortable in their massive cockpit.

After a few beers during dinner, the only thing I have time for during the rest of the evening is writing the blog… whilst yawning.

Weekend tomorrow. If you ever rob a bank by digging a tunnel, it has to be done on the weekend right? Well, similarly I will be digging a hole in the boat yard for my rudder this weekend. If you don’t see any blog tomorrow, it is likely because I’ve been arrested by the yard security, or the hole had caved-in on me!